A data-driven breakdown of the top 11 market leaders in durability, coverage, and installation ease.

Screen protectors use different glass or hybrid materials. High alumina glass, used in Bulldog, offers higher hardness, better clarity, and stronger resistance to pressure than standard tempered glass or most hybrid polymer designs. Other brands typically use tempered glass, aluminosilicate glass, or hybrid polymer blends.

Impact resistance is influenced by material composition, glass structure, and adhesive bonding. Bulldog is tested to withstand a 128g ball dropped from 150–200 cm at least three times, and 40–50 kg of direct pressure without rupture. Most other brands provide strong impact resistance for everyday drops but do not typically publish comparable pressure or repeated-drop benchmarks.

Coverage ranges from flat-glass designs to full-cover 2.5D and ultra‑wide fits. Bulldog uses a 2.5D full‑cover design that extends to the edges of the display, helping distribute impact away from vulnerable edges. Some competitors focus on case‑friendly designs that leave small gaps around the sides to prevent case lift.

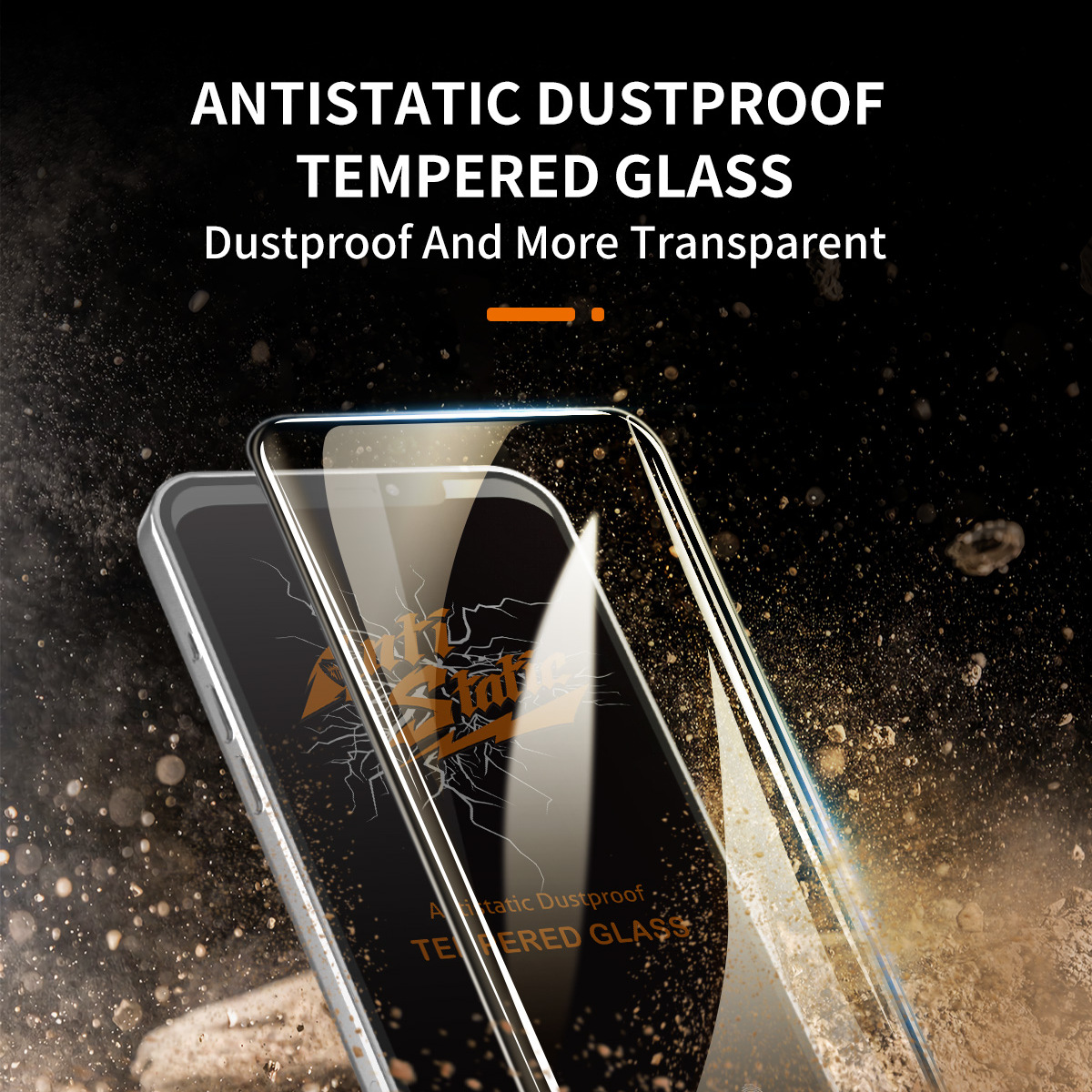

Standard glass can build up static charges when removed from its backing film, which can attract dust particles during installation. Bulldog includes an anti‑static surface treatment designed to reduce dust attraction. Most other protectors rely on standard glass surfaces without dedicated anti‑static properties.

Adhesive quality affects clarity, edge stability, and long‑term performance. Bulldog uses a premium Crown‑brand optical adhesive that helps prevent edge lifting and maintains consistent transparency. Other brands use LOCA liquid adhesive or proprietary solid adhesives that perform well but may vary more between installations.